-

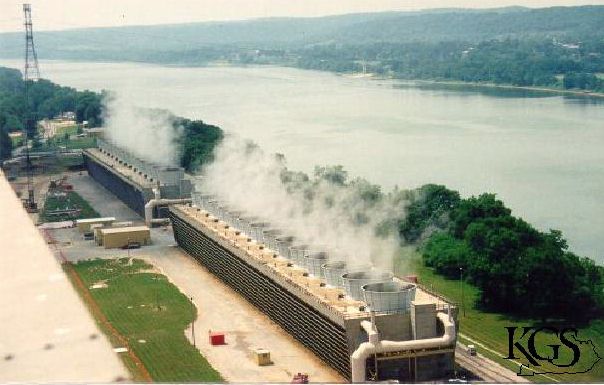

Cooling Tower

Water Conservation

Cooling towers represent the largest use of water in commercial buildings, up to 50% of total water use. Reduce this water consumption by over half!

-

Stop All Iron & Rust Stains

Without An Iron Filter

Advanced treatment gives your water softener the power to stop all iron stains, guaranteed!

-

Eliminate Scale & Bio Problems In

Infra-Red Humidifiers

Reduce maintenance, odors & biological fouling while improving vapor quality.

-

Scale & Full-Size Locomotive

Steam Boiler Treatment

Advanced technology single-feed treatment with exceptional scale & corrosion control. No hazardous phosphates, nitrites, caustics or sulfites tender to exhaust.

Cooling Tower Water Conservation

Standard cooling tower water treatment programs require 33% to 50% waste water discharge in order to prevent scale formation. Even in a relatively small cooling tower, this can add up to hundreds of thousands of gallons of fresh water wasted annually. With water costs on the rise and severe drought in some areas of the country, now is the perfect time to upgrade your water-wasteful cooling tower water treatment program to the Terlyn Cooling Tower Water Conservation Program.

Stop All Iron Staining Without An Iron Filter!

Advanced rust treatment gives your water softener

the power to stop all iron stains, guaranteed

Eliminate

Iron/Rust

Stains

Stop All

Well Water

Rotten Egg

Odors

Replace An

Expensive

Iron Filter

Vapure Humidifier Treatment

Custom-formulated, pre-mixed in heavy-guage plastic gallon

Reduces pan scale, odors and biological fouling

Advanced technology, with 10+ years of proven performance

Improves system performance

FDA and USDA approved

No pesticides

No EPA registration required

Safe handling

24v factory-calibrated feed pump

Locomotive

Boiler

Treatment

We have developed the most advanced locomotive water treatment on the market. We have separate single-feed products for both full-size and scale locomotives both specifically designed to control scale and corrosion in live steam boilers while removing existing deposits.

The outstanding performance of LSB4000 has been proven world-wide on hundreds of saturated and superheated

steam engines using both softened and raw water make-up.

Peristaltic Feed Pumps

Terlyn CVX Peristaltic Feed Pumps are an accurate and inexpensive method of metering a wide variety of fluids and liquid chemicals without product contamination. The CVX pump is a masterpiece of simplicity. Its quiet compact design makes it suitable enough to withstand the hars environments of industrial applications. With only three moving parts, reliability of the CVX pump is exceptional and the peristaltic design offers many advantages.